Description

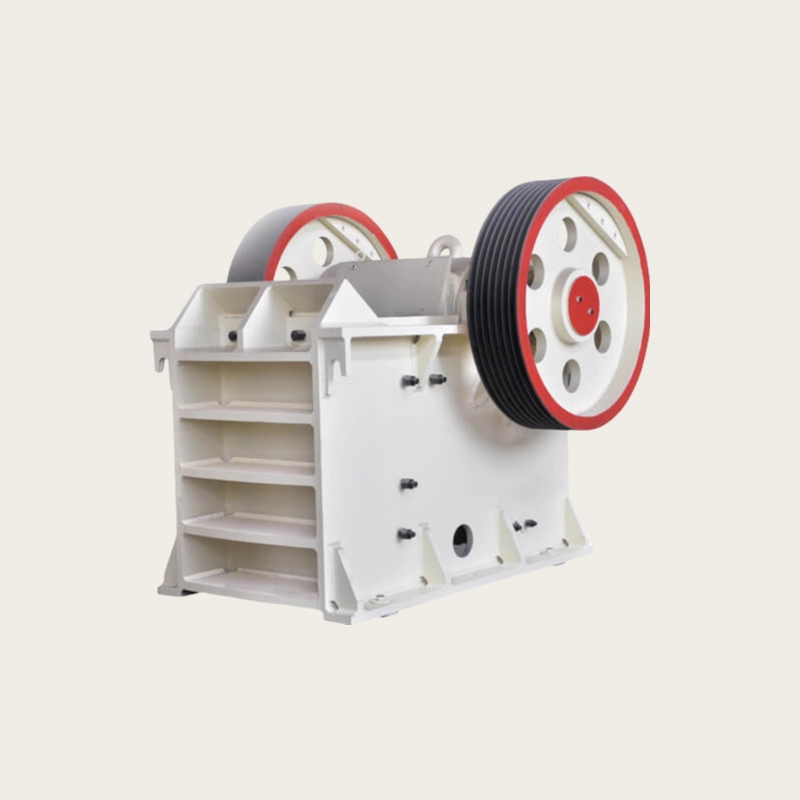

Name: Sand maker,sand maker machine

Feed particle size: ≤ 50mm

Motor power: 7.5-18.5kw

Production capacity: 1-10T / h

Applicable materials: rock gold, granite, tungsten tin, tantalum niobium, limestone, tailings dissociation, etc

Description

Sand maker mainly breaks materials by impact. The materials enter the hammer crusher and are crushed by the impact of the high-speed rotating hammer head. The crushed materials obtain kinetic energy from the hammer head of the hammer crusher and rush to the baffle and screen strip in the frame at high speed. At the same time, the materials collide with each other and are crushed for many times. The materials smaller than the gap between the screen strips are discharged from the gap, and some larger materials, On the screen strip, it is crushed again by impact, grinding and extrusion of the hammer head, and the material is extruded from the gap by the hammer head of the hammer breaker. So as to obtain the product with the required granularity.

Advantages:

1. Simple structure: the body structure is sealed, the design is beautiful, and the problem of material leakage and slurry leakage is solved

2. Adjustable particle size: the screen or screen strip can be changed according to the customer’s requirements to control the discharge particle size

3. Wear resistant. Durable and impact resistant: the hammer head is cast by new technology, with few vulnerable parts and convenient maintenance

4. Large crushing ratio: high production efficiency, small and uniform product particle size

| Model | Capacity(t/h) | Max feeding size(mm) | Discharging size(mm) | Motor(kw) | Diesel(hp) |

| DS200*500 | 1-3 | ≤50 | ≥1.8 | 15-18.5 | 24 |

| DS300*500 | 3-6 | 18.5-22 | 30 | ||

| DS400*500 | 5-10 | 22-30 | 45 | ||

| DS600*500 | 8-12 | 22-37 | 60 | ||

| DS600*800 | 10-15 | 30-45 | 80 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Copper Ore Partial Mixed Flotation Process

- Tin ore flotation processing technology

- Gravity beneficiation process for iron ore

- Cyanide Gold Preparation

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Gravity combined beneficiation process for black and white tungsten ore

- Lithium ore combined beneficiation process

Leave a message with your needs or comments

Add comment: