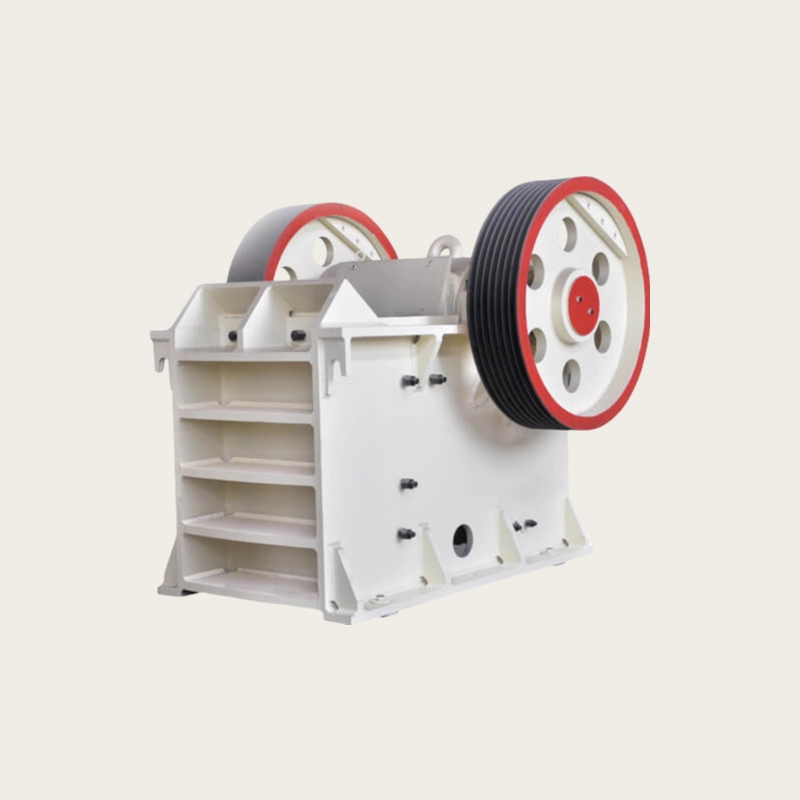

Depending on the number of rolls, roll crushers are classified into single-roller type and double-roller type, while according to the smoothness of the rollers, they are classified into single-roller type or hobbing type.

Double-toothed roller crushers are commonly used in mineral processing plants. The crushing ratio is 3~15. and the particle size must not exceed 25mm.

Description

Name: Roller Crusher, Double Roller Crusher, Toothed Roll Crusher, Double toothed roll crusher

Motor power: 75kw

Feed particle size: ≤40mm

Production capacity: 5-110t/h

Uses: Crushing medium and high-hardness materials in metallurgy, construction, refractory materials and other industries.

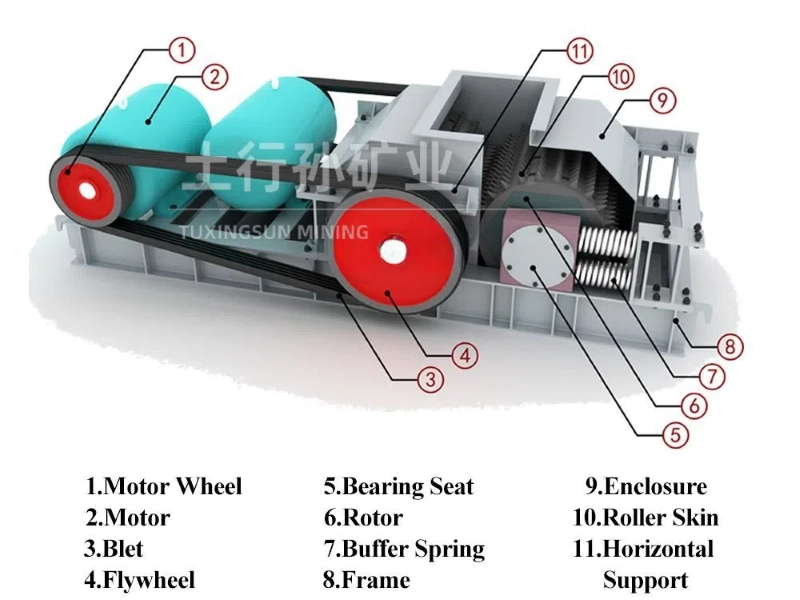

Structure: Roller assembly, roller support bearing, pressing and adjusting device, drive device, etc.

The double-toothed roll crusher is also called the toothed roller crusher. These crushers are widely used for coarse and intermediate crushing of brittle block materials in mining, metallurgy, building materials, refractory materials, chemical industry, coal, and building construction materials. In the coal industry, the raw coal can be crushed directly as long as it has been cleaned of iron and impurities, and no gangue has been removed. investment and production costs.

Structural Features

1.The hydraulic double-roller mill can fully utilize the sand-making equipment’s production capacity when it is used in the sand making production line.

2.In the interior is a dust-proof plate which has good sealing performance and prevents small materials from splashing after crushing, with less dust and low working noise, and the working environment is greatly improved.

Working Principle

The toothed roll crusher is powered by two motors, which are transmitted through the V-belt through the sheave pulley to drag the roller and rotate in accordance with the relative direction. The crushed material is crushed by the roller from the feed port, and the crushed product is discharged from the bottom.

Features

1.The structure is compact, the output is increased by about 30%-40%, the energy consumption can be reduced by about 20%-30%, no blocking, small size, small space occupied, and investment savings.

2.The discharging granularity can be adjusted quickly with a handwheel or hydraulic structure with a simple structure and little maintenance.

3.Roller skin has a long service life and is thickened: the roller skin is made of wear-resistant material, which is harder to damage and can last a long time.

4.The over-crushing rate is low and the particle size is adjustable, so it can meet various specifications and materials and meet various needs. The smaller the gap, the finer the discharge.

5.The whole machine is equipped with an automatic lubrication system made of high-strength steel, which makes the maintenance and operation of the machine safer.

6.There are two powerful motors, which run smoothly and have high crushing efficiency. The motors are replaceable for free during the warranty period. Our factory uses brand motors with a manufacturer’s guarantee of quality.

7.Plenty of sundries utilize the integrated balance flashback protection of the liquid spring, the automatic retreat technology. When a flexible object enters a crusher and cannot be broken, it quickly returns to the original gap position to maintain continuous operation.

| Model | Technical properties | Motor(kW) | Dimension(mm) | Weight(kg) | ||

| Feeding size(mm) | Output size(mm) | Capacity(t/h) | ||||

| 2PGC400x250 | <16 | 2-5 | 2.3-2.5 | 2×5.5 | 2245x940x718 | 3600 |

| 2PGC310x400 | <36 | 2-9 | 3-9 | 2×11 | 1785x2365x1415 | 3800 |

| 2PGC750x500 | <40 | 2-10 | 7-12 | 2×15 | 2720x2700x1400 | 10250 |

| 2PGC750x700 | <40 | 5-10 | 15-25 | 2×22 | 3422x2800x1705 | 11700 |

| 2PGC750x1000 | <40 | 2-10 | 6-30 | 2×30 | 4150x2800x1750 | 12500 |

| 2PGC900x500 | <40 | 2-10 | 9-30 | 2×22 | 2750x1790x2065 | 14000 |

| 2PGC900x900 | <40 | 2-10 | 11-45 | 2×30 | 2750x2180x2065 | 16800 |

| 2PGC900x1200 | <40 | 3-10 | 15-60 | 2×55 | 2750x2480x2065 | 20800 |

| 2PGC900x800 | 25-90 | 3-40 | 12-50 | 2×45 | 2940x2080x2065 | 22600 |

| 2PGC1200x1000 | <40 | 3-12 | 10-50 | 2×37 | 3690x3430x2700 | 46820 |

| 2PGC1200x1200 | <40 | 3-12 | 18-68 | 2×75 | 3690x3630x2700 | 14600 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Copper Ore Partial Mixed Flotation Process

- Tin ore magnetic separation+electric separation process

- Iron Ore Weak Magnetic Beneficiation Process

- Gold selection process using resin slurry method

- Cyanide Gold Preparation

- Prioritized Flotation Process for Lead-zinc Ore

- Branch serial flow flotation process for lead-zinc ore

Leave a message with your needs or comments

Add comment: