Description

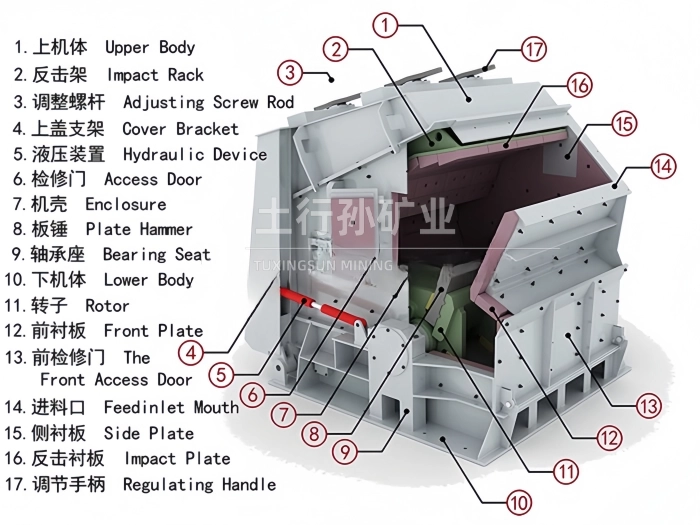

Product Name: Impact Crusher, Impact crusher machine, Impact crusher manufacturer,Impact hammer mill

Capacity: 15-550(t/h)

The impact hammer mill is designed for crushing coarse, medium and fine materials (granite, limestone, concrete, etc.) whose side length does not exceed 500mm and compressive strength does not exceed 350 MPa, and is widely used in the mining, highway, railway, and construction industries. Process. Advanced structure, high-chromium blow hammer, unique impact lining plate; hard rock crushing, high efficiency, low energy consumption; product shape is cubic, and the discharge size can be adjusted to simplify crushing. To protect the environment, it can be equipped with new equipment for removing dust.

According to the impact hammer mill working principle, an impact crusher smashes materials using the principle of impact crushing. Impact crushers are finer than jaw crushers. Crusher for cooperative jaw crushing.

Five advantages of the impact crusher in the crushing process are listed below.

1. The impact hammer mill can handle wet materials without material blocking.

2. Impact crushers are better suited to hard materials.

3. The particle size of the discharge can be easily and flexibly adjusted.

4. Minimal wear of vulnerable parts and high metal utilization.

5. Impact crusher spare parts can be easily replaced, which reduces maintenance costs

Impact crushers are equipped with only six plate hammers. Designed tools can easily be used to replace the plate hammers. A set of plate hammers can be replaced in one shift.

Working Principle

Advantage

2. The gap between the impact plate and the plate hammer can be easily adjusted, effectively controlling the particle size and particle shape.

3. Compact, rigid, and with a large moment of inertia, the machine has a compact structure.

4. Chrome plate hammer with high impact force, impact resistance, and wear resistance.

5. Convenient keyless connection, economical, and reliable.

6. Comprehensive crushing functionality, high productivity, low mechanical wear, and high efficiency.

| Model | Specification (mm) | Feeding size(mm) | Max feeding edge(mm) | Capacity(t/h) | Power(kw) | Weight(t) | Overall dimension(l*w*h)(mm) |

| PF-1007 | Φ1000*700 | 400*730 | 300 | 25-45 | 30-55 | 9.5 | 2400*1558*2660 |

| PF-1010 | Φ1000*1050 | 400*1080 | 350 | 50-80 | 55-75 | 12.2 | 2400*2250*2620 |

| PF-1210 | Φ1250*1050 | 400*1080 | 350 | 80-120 | 110-132 | 14.1 | 2690*2338*2890 |

| PF-1214 | Φ1250*1400 | 400*1430 | 350 | 110-132 | 132-160 | 18.6 | 2690*2688*2890 |

| PF-1310 | Φ1300*1050 | 490*1170 | 400 | 132-160 | 110-160 | 16.2 | 2780*2478*2855 |

| PF-1315 | Φ1320*1500 | 860*1520 | 500 | 180-260 | 180-260 | 19.3 | 3096*3273*2667 |

| PF-1415 | Φ1450*1500 | 900*1650 | 500 | 260-280 | 260-280 | 24 | 3400*3500*3280 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Magnetic separation and beneficiation process for bauxite

- Gold Ore Thiourea Beneficiation

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Gravity combined beneficiation process for wolframite ore

- Lead-zinc Ore Asynchronous Flotation Process

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

- Understanding the Manganese Ore Flotation Process

Leave a message with your needs or comments

Add comment: