In the overall process of the dressing plant, grinding operations aim at fully separating useful minerals from the ore. From the perspective of economic benefits, grinding is even more important. The investment of grinding operations in the dressing plant accounts for more than 30% of the total investment. Therefore, it is of great significance to improve the grinding operation efficiency for improving the overall economic benefit of the dressing plant.

01 Ore Properties

The composition and physical properties of the ore have a great influence on the efficiency of grinding technology. For example, when the useful minerals in the ore have a coarser grain size and a loose and brittle structure, they are easier to grind. However, it is more difficult to grind when the grain size of the useful minerals becomes finer, denser and harder.

Generally speaking, coarse grain size particle are easier to grind and faster to produce qualified particle sizes in coarse grinding, while fine grinding is more difficult. As the particle size decreases, the fragile surface of the material also decreases, that is, particle becomes harder and harder, so the speed of producing qualified particle size is slower. Therefore, the grinding efficiency of coarse grinding is higher than fine grinding.

02 Equipment Factors

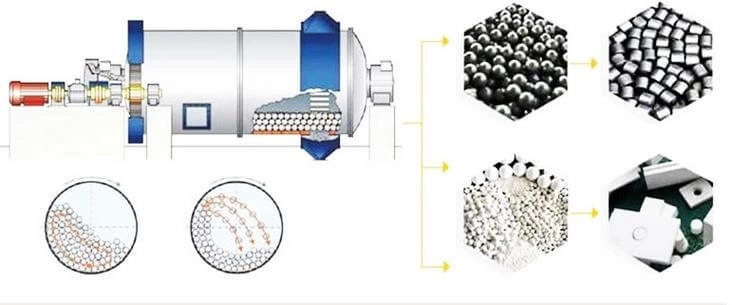

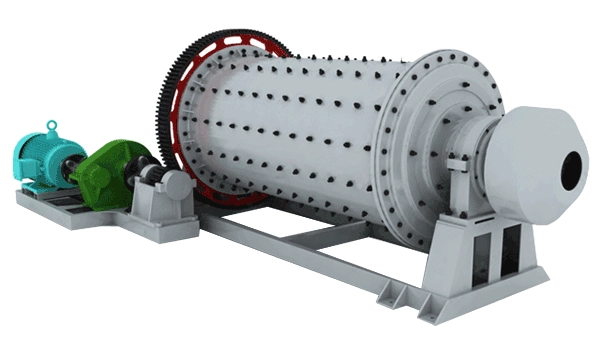

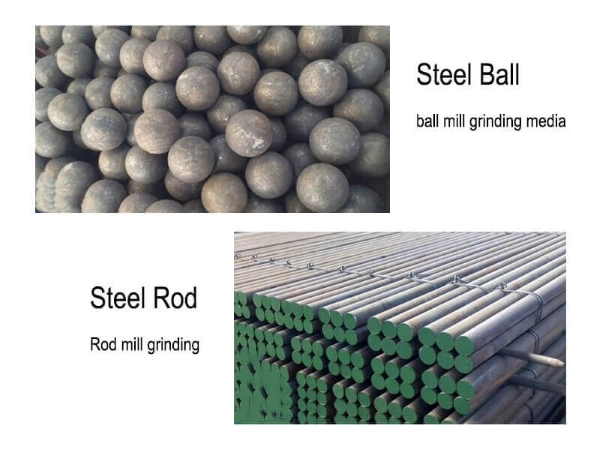

The selection and use of grinding equipment also has a certain influence on the grinding efficiency. For example, when the main grinding equipment is ball mill, the speed of the ball mill, the filling coefficient of the steel ball and the size of the grinding medium all have different effects on the final grinding efficiency.

(1) The speed of ball mill

The speed of ball mill directly affects the motion state of steel balls and ores in the ball mill. When the speed is too slow, the steel balls and ore will slide down without rising high, and the crushing effect will be small; when the speed is too fast, the grinding medium will attach to the inner wall of the ball mill and rotate. The ore and the steel ball will stop grinding.

Only when the rotation speed is appropriate, the ball can take the raw materials to rise to a certain height along the wall of the cylinder. When the component of gravity is equal to the centrifugal force, the grinding medium falls along the parabolic orbit and hits the ore or steel ball below. At this time, the ore is subjected to the maximum impact force and grinding action, and the grinding efficiency is the highest.

(2) Steel balls in ball mill

The most suitable loading degree of steel balls in ball mill is 80% to 90% of the total volume. Generally, it is better when the total load does not exceed four-fifths of the total capacity of ball mill. The size and gradation of steel balls depends on the diameter of ball mill.

03 Operating Factors

Firstly, the operation of the operator is undoubtedly another important factor affecting the efficiency of the grinding operation.

For example, in the closed-circuit grinding stage, when the sand-returning ratio is too large and exceeds the normal passing capacity of the grinding machine, the phenomenon of running coarse will appear in the grinding products. While the sand-returning ratio is too small, or there is no sand return, it is easy to cause over-grinding.

If the load is too large, the running coarse phenomenon in the grinding product will be serious, and if the load is insufficient, the over-grinding will be serious. Therefore, when operating the mill, the technician must ensure that the ore feed in evenly and steadily. If the amount of ore is sometimes large or small, it will affect the improvement of grinding efficiency.

Secondly, the grinding concentration will also have a certain influence on the grinding efficiency.

Because the grinding concentration directly affects the grinding time, if the concentration is too large, the material will flow slowly in the mill, the grinding time will increase, and it will be easy to result in over-grinding. In addition, the coarse particles are not easy to sink in the high-concentration slurry, and are easy to flow away with the slurry, resulting in running coarse.

If the slurry concentration is too thin, the flow speed of material will increase. The grinding time is shortened also result in running coarse. And large-density ore particles are easy to deposit on the bottom of the slurry, which can also cause over-grinding.

Therefore, the appropriate grinding concentration should be controled well in operation, which requires strict control of water volume. Generally speaking, the concentration of coarse grinding is usually 75-85%, and the concentration of fine grinding is generally 65-75%.

04To Wrap Up

The above are the three major aspects that affect the grinding efficiency. How about your ball mill? If your ball mill are lower efficiency, you could from the article looking your answer.

It should be noted that:

Prevent over-grinding and running coarse, obtain a more suitable grinding particle size.

Improve the technical level of the operators.

Purchase your grinding equipment from manufacturers with the overall qualifications of the dressing plant.

If you have different views or questions about the ball mill capacity, welcome to submit a message and inquire our online service.

- Random article

- Popular articles

- Popular comments

- Carbon leaching beneficiation process for gold mines

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Lead-zinc Ore Asynchronous Flotation Process

- Branch serial flow flotation process for lead-zinc ore

- Lithium ore combined beneficiation process

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

- Zirconium Ore Separation: Gravity and Magnetic Methods

Leave a message with your needs or comments

Add comment: