Manganese is an essential element used in various industries, including steel production, batteries, and electronics. To extract and process manganese effectively, beneficiation machines play a crucial role. These machines are designed to separate and concentrate manganese ores, improving their quality and making them suitable for further processing. In this article, we will explore the top 10 manganese beneficiation machines that ensure efficient processing and enhance the overall productivity of manganese mining operations.

Shaking table for manganese beneficiation

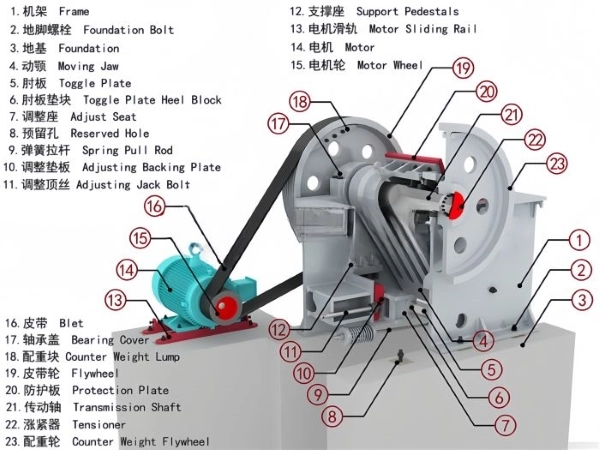

01Jaw Crusher

Jaw crushers are commonly used in the initial stage of manganese ore processing. They are designed to crush large chunks of manganese ore into smaller particles that can be easily processed by other beneficiation machines. Jaw crushers are equipped with a fixed jaw and a movable jaw, which work together to crush the ore. The crushed ore is then fed into other beneficiation machines for further processing.

Jaw crusher - top 10 manganese beneficiation machines

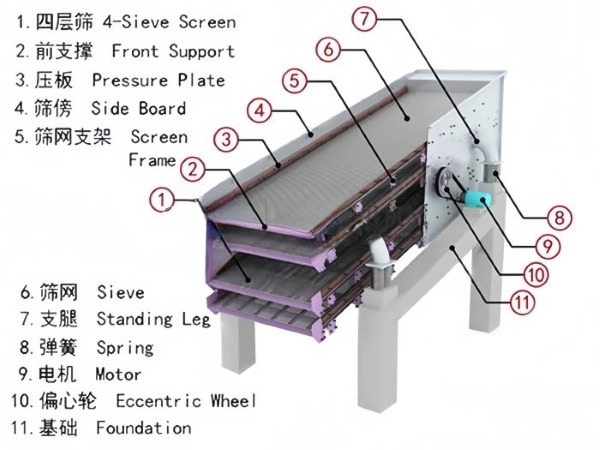

02Vibrating Screen

Vibrating screens are used to separate the manganese ore into different particle sizes. They are essential for the efficient processing of manganese ore, as they help to classify the ore into different grades and improve the quality of the final product. Vibrating screens use vibrating motors to screen the manganese ore. The screened ore is then collected and sent for further processing.

Vibrating screen - top 10 manganese beneficiation machines

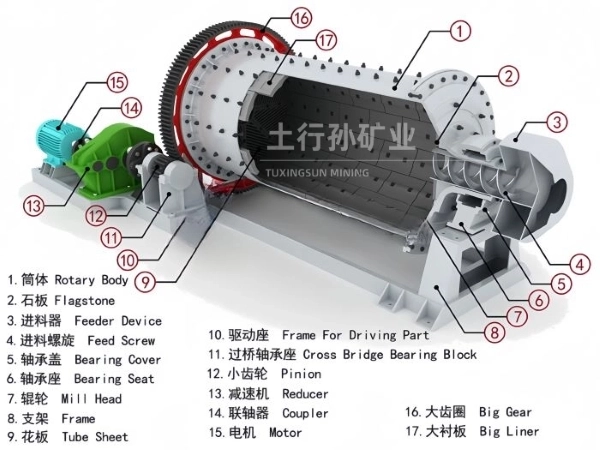

03Ball Mill

Ball mills are used to grind the crushed manganese ore into a fine powder. They are essential for the efficient processing of manganese ore, as they help to reduce the particle size of the ore and increase its surface area. This allows for better interaction between the ore and the beneficiation chemicals, leading to higher recovery rates and better product quality. Ball mills are commonly used in the final stage of manganese ore processing before the ore is sent for further beneficiation.

Ball mill - top 10 manganese beneficiation machines

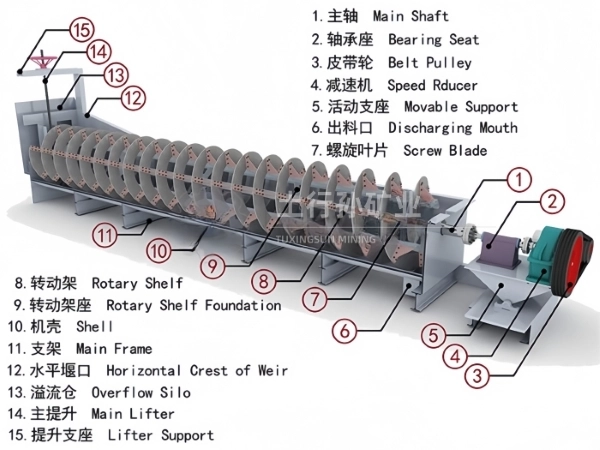

04Spiral Classifier

Spiral classifiers are essential machines for classifying mineral particles based on their size, shape, and density. By using a spiral motion, these devices separate manganese ores into different size fractions, allowing for efficient beneficiation. The classified products can then be further processed based on their specific properties.

Spiral classifier - top 10 manganese beneficiation machines

05Hydrocyclone

Hydrocyclones are used for classifying and separating solids from liquids or suspensions based on particle size. In manganese beneficiation, hydrocyclones are employed to remove fine particles and slimes from the ore mixture, improving the efficiency of subsequent processing steps.

Hydrocyclone - top 10 manganese beneficiation machines

06Magnetic Separator

A magnetic separator is a widely used machine in manganese beneficiation. It utilizes magnetic differences between minerals to separate magnetic materials from non-magnetic ones. By applying a magnetic field, this machine effectively concentrates manganese ore, removing impurities and increasing the ore grade.

Magnetic separator - top 10 manganese beneficiation machines

07Jig Machine

Jig machines are gravity separation devices that utilize the pulsating water flow to separate minerals based on their density. They are particularly effective in processing coarse-grained manganese ores. The jigging action allows the denser manganese particles to settle while lighter gangue materials are washed away, resulting in a higher concentration of manganese.

08Shaking Table

Shaking tables are another gravity-based separation technique, often used in combination with jig machines. This equipment uses a shaking motion to separate minerals based on their specific gravity. By adjusting the table's slope and water flow, manganese ores can be separated into different grades, facilitating the beneficiation process.

Shaking table - top 10 manganese beneficiation machines

09Flotation Machine

Flotation machines are widely used in mineral processing to separate valuable minerals from gangue materials. In manganese beneficiation, flotation is utilized to separate manganese minerals from other associated minerals. By creating a froth layer on the surface of the pulp, the flotation machine selectively attaches to the manganese particles, ensuring their separation.

Flotation machine - top 10 manganese beneficiation machines

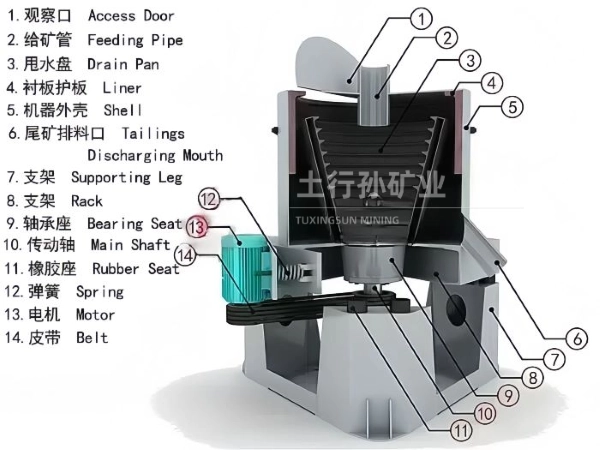

10Centrifugal Concentrator

Centrifugal concentrators are devices that utilize centrifugal force to enhance the gravitational field and separate different minerals based on their density. In manganese beneficiation, centrifugal concentrators can efficiently recover manganese minerals from low-grade ores or tailings, increasing the overall yield of the beneficiation process.

Centrifugal concentrator - top 10 manganese beneficiation machines

11Conclusion

Manganese beneficiation machines are essential tools for efficient processing of manganese ores. The top 10 machines discussed in this article, including magnetic separators, jig machines, shaking tables, hydrocyclones, spiral classifiers, flotation machines, high-intensity magnetic separators, centrifugal concentrators, magnetic pulsating separators, and electrostatic separators, offer a diverse range of options to enhance productivity and improve the quality of manganese concentrates. By utilizing these machines, mining operations can maximize their production efficiency and achieve higher returns on investment.

Don't settle for subpar manganese concentrate. Upgrade your beneficiation machines and achieve higher grades and increased productivity. Get in touch with our specialists to discuss your specific requirements!

- Random article

- Popular articles

- Popular comments

- Gold Ore Carbon Slurry Beneficiation Process

- Gravity combined beneficiation process for wolframite ore

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Zirconium Ore Processing: Gravity Separation and Flotation

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Rutile Gravity Separation, Magnetic Separation, and Flotation Process

- Rutile Processing: Gravity, Magnetic, Flotation, Electric Separation

Leave a message with your needs or comments

Add comment: