Pyrite is a general term for sulfide minerals of iron, generally including pyrite, pyrrhotite, and white iron. Pyrrhotite is the most common, pyrrhotite is rare, and white iron is extremely rare. The beneficiation process of pyrite can be divided into three types: single flotation, single gravity separation, and gravity flotation combined method; Single flotation is mainly used to treat pyrite with finer embedded particle size; Single re selection is suitable for processing coarse-grained embedded pyrite ores; The combined process of re selection and flotation is used to treat pyrite with uneven particle size distribution.

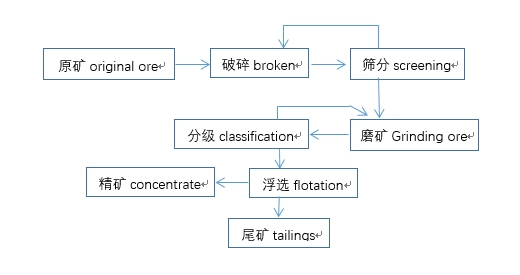

Flotation process

The raw ore is directly flotation of pyrite after crushing and grinding.

For a single pyrite ore, xanthates such as ethyl xanthate, butyl xanthate, and isobutyl xanthate can be used as collectors to effectively recover pyrite. In some cases, pyrite undergoes a certain degree of oxidation, which weakens its floatability. Activators such as sulfuric acid and oxalic acid need to be added to improve the recovery rate of flotation.

When pyrite coexists with other valuable metal sulfides such as chalcopyrite, galena, sphalerite, etc., pyrite is often removed as an impurity. Therefore, it is necessary to suppress pyrite during flotation to improve the grade of the target mineral. Generally, inhibitors such as lime, sodium sulfide, and sodium humate are used to suppress pyrite in alkaline flotation environments.

However, when pyrite coexists with other valuable metal sulfide ores and has certain recycling value, the activation of suppressed pyrite needs to be considered. Sulfuric acid, copper sulfate, lead nitrate, etc. can be used as activators for pyrite, and then the pyrite can be recovered by flotation. In production practice, the combination of two or more activators for the activation of iron sulfate can often achieve better flotation results

Process characteristics

high recovery rate and high grade

Typical beneficiation plant

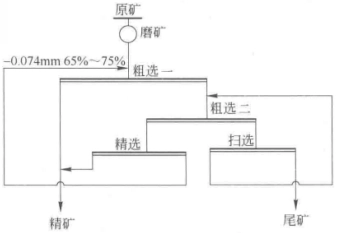

Guangdong Yunfu Pyrite Mineral Processing Plant. Yunfu Pyrite comes from two different mining areas, and the low-quality mining area has a lower sulfur grade. The ore structure is mainly strip-shaped and dense block shaped, with fine distribution of useful minerals and high content of carbonaceous and calcium magnesium. The selection process is as follows

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Reverse flotation beneficiation process for bauxite

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Lithium ore positive flotation process

- Uranium Ore Radioactive Treatment Process

- Antimony Ore Hand Picking Process for Color Sorting

- Molybdenite Grinding and Separation Process

- Copper-Molybdenum Ore Separation & Flotation Process

Leave a message with your needs or comments

Add comment: