The entire process of cyanide leaching for gold extraction, what is it like?

The entire process of cyanide leaching for gold extraction is as follows: The cyanide process involves using a reagent to react with the ore, dissolving the gold from the ore into the reagent solution. The gold is then adsorbed and replaced, initially concentrated, and then refined through smelting to obtain the final product of gold bullion.

The Cyanide Leaching Process for Gold ExtractionCyanide leaching, also known as the cyanide process or the MacArthur-Forrest process, is a hydrometallurgical technique for extracting gold from low-grade ore. Here's a general overview of the process:

1. Ore Preparation

Mining: The gold-bearing ore is extracted from the ground.

Comminution: The ore is crushed and ground to a fine particle size to liberate the gold particles. This is typically done in stages, using crushers and ball mills.

2. Cyanidation

Leaching: The crushed ore is mixed with a dilute cyanide solution (sodium or potassium cyanide) in large tanks or heaps. The cyanide reacts with the gold to form a soluble gold cyanide complex.

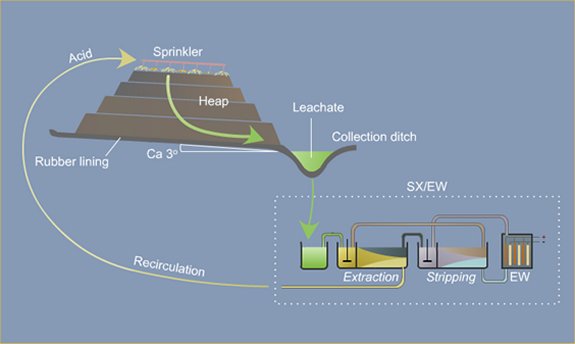

Tank leaching: The ore is placed in tanks and agitated with the cyanide solution.Heap leaching: The ore is piled into large heaps and the cyanide solution is sprayed over it.

3. Gold Recovery

Adsorption: The gold-laden cyanide solution is passed through activated carbon columns. The gold is adsorbed onto the carbon surface.

Desorption: The gold-loaded carbon is stripped of gold using a strong caustic cyanide solution under pressure and heat. This process is called elution.

Electrowinning: The gold-bearing solution from elution is subjected to electrolysis, where gold is deposited on cathodes.

Refining: The recovered gold is further refined to produce high-purity gold bullion.

4. Tailings Management

The spent ore (tailings) is carefully managed to prevent environmental contamination.

It's often stored in tailings dams.

Key points to remember:Cyanide is a highly toxic substance and requires strict handling and disposal procedures. The process is efficient in recovering gold from low-grade ores.

Environmental concerns related to cyanide use have led to the development of alternative gold extraction methods in recent years.

- Random article

- Popular articles

- Popular comments

- Reverse flotation beneficiation process for bauxite

- Tin ore gravity separation+roasting+magnetic separation+gravity beneficiation process

- Carbon leaching beneficiation process for gold mines

- Cyanide Gold Preparation

- Lithium ore combined beneficiation process

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

- Radioactive beneficiation and flotation process for uranium ore

Leave a message with your needs or comments

Add comment: