When conducting carbon slurry cyanidation, what are the minimum requirements for the gold ore?

The minimum requirements for carbon slurry cyanidation are grade and recovery rate. It is crucial to conduct experiments to determine the optimal processing method for the ore.

Minimum Requirements for Gold Ore in Carbon-in-Pulp (CIP) Cyanidation

The suitability of a gold ore for carbon-in-pulp (CIP) cyanidation depends on several factors, including mineralogy, liberation, and the presence of interfering elements. While there's no strict set of minimum requirements, the following characteristics generally favor the CIP process:

Mineralogy

Free gold: Gold that is readily accessible to the cyanide solution is ideal.

Refractory gold: Gold encapsulated in sulfide minerals or other refractory phases may require additional pretreatment or alternative processes.

Telluride minerals: Gold associated with tellurium can be challenging to recover using CIP, often requiring additional processing steps.

Liberation

Particle size: Adequate liberation of gold from the gangue minerals is essential for efficient cyanide leaching and gold adsorption onto the activated carbon. Fine grinding is often required.

Interfering Elements

Cyanide consumption: High levels of certain elements, such as copper, zinc, and nickel, can consume cyanide and reduce gold extraction.

Carbon poisoning: Some elements, like sulfur and organic compounds, can poison the activated carbon, reducing its adsorption capacity.

Additional Considerations

Ore grindability: The ore's hardness and grindability will influence energy consumption and grinding costs.

Ore moisture content: High moisture content can affect slurry density and process efficiency.

Cyanide solubility: The ore's pH and the presence of certain minerals can affect cyanide solubility and gold extraction.

In summary, while the CIP process is versatile, ores with free gold, good liberation, and minimal interfering elements are generally more amenable to this method.

It's important to conduct thorough metallurgical testing on the ore to determine its suitability for CIP and to optimize process parameters.

- Random article

- Popular articles

- Popular comments

- Selective flocculation beneficiation process for bauxite

- Hg-ore gravity separation process

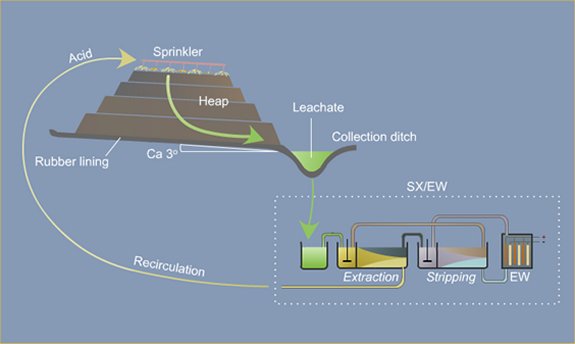

- Gold Ore Carbon Slurry Beneficiation Process

- Lead zinc ore mixing+separation flotation process

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Lithium ore reverse flotation process

- Lithium ore magnetic separation process

Leave a message with your needs or comments

Add comment: