Gold can be extracted directly from oxidized ores with large mud content using a carbon-separating screen, also known as carbon slurry (leaching).

There is a rapid turnover of capital and a high recovery rate among its characteristics

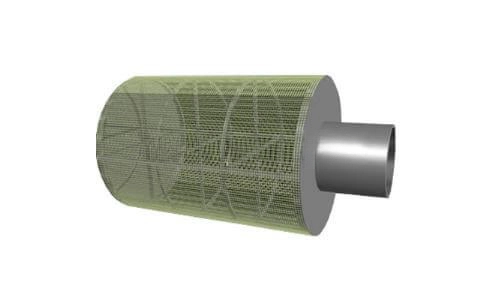

Description

Name: carbon separator, carbon separation screen

Features: This product is installed in the carbon leaching tank, the function is to separate the pulp and activated carbon

Selection instructions: Additionally, when ordering a screen, it is necessary to specify the model and quantity, as well as the type and material. There are no special instructions for processing and manufacturing according to the drawings provided by the manufacturer.

Sieve diameter: 300mm

Screen frame length: 1000mm

Screen size: 28 mesh, 20 mesh

Weight: 20kg, 35kg

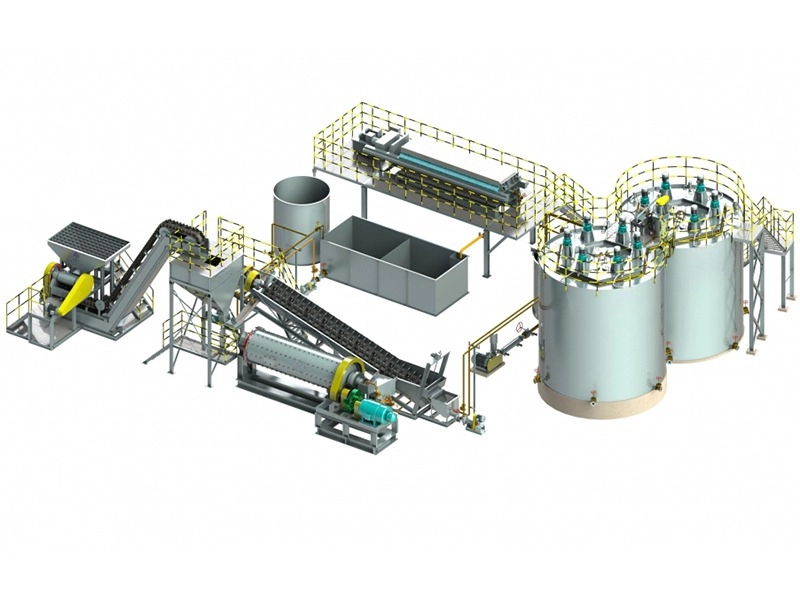

With the carbon separation screen, also known as the carbon pulp (leaching) method, alloyed gold can be obtained directly from oxidation ores with large mud contents. Its characteristics include high recovery rates and fast capital turnover.

Application

Activated carbon separation is carried out in the leaching tank of the Cyanide Carbon Pulp Plant.

favorable conditions.

The sieve hole is not easy to be blocked; the structure is simple, the operation and maintenance are convenient; the cost is low; the service life is long.

The carbon screen is used in the cyanidation carbon pulp plant, and the activated carbon is separated from the pulp by the screen, so that the pulp flows to the next leaching tank by itself, and the activated carbon remains in the leaching tank.

The leaching tank of the Cyanide Carbon Pulp Plant is used to separate activated carbon.

Favorable Conditions

There is no easy way to block the sieve hole; the structure is simple, the operation and maintenance are convenient; the cost is low; the service life is long.

Activated carbon is separated from the pulp by the carbon screen in the cyanidation carbon pulp plant, so that the pulp flows to the next leaching tank by itself, while the activated carbon remains in the leaching tank.

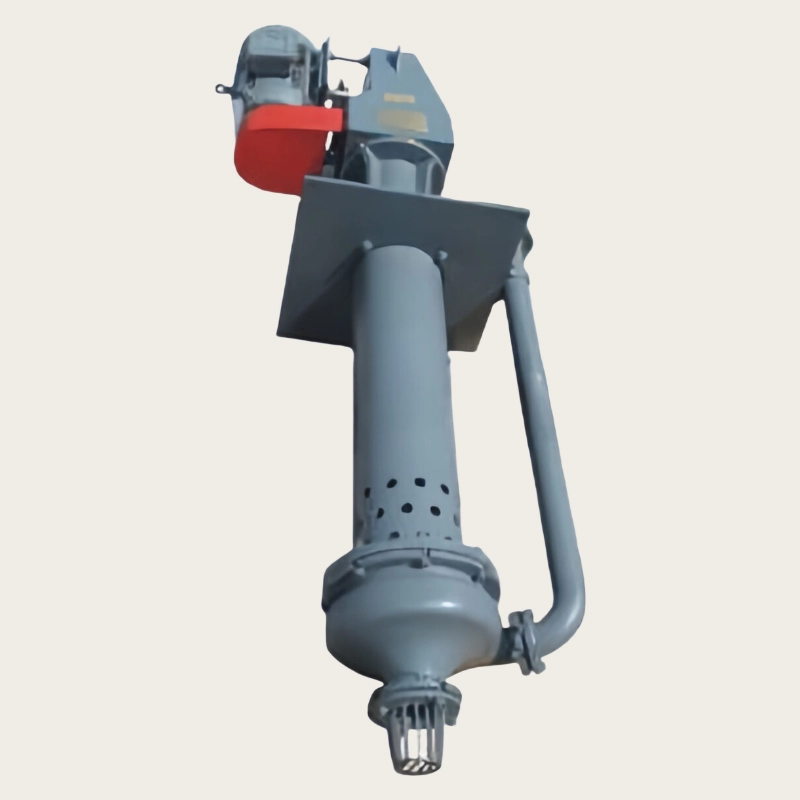

The solution to the clogging failure of the carbon separator

When pulp quality is excessive, viscosity is high, bottom carbon density is high, or impurities like sawdust are present in the pulp, the carbon screen is often blocked, resulting in running grooves and metal loss.

Solution

1. Increase sawdust removal.

2. Reducing pulp mass fraction or bottom carbon density appropriately.

3. Make sure the low-pressure air volume is increased properly for removing carbon deposits from the screen.

| Model | Sieve Diameter(mm) | Screen frame length(mm) | Screen size(mm) | Weight(kg) |

| SG300 | Φ300 | 1000 | 28 | 20 |

| SG500 | Φ500 | 1000 | 20 | 35 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Selective flocculation beneficiation process for bauxite

- Intense Magnetic Separation Process for Iron Ore

- Prioritized Flotation Process for Lead-zinc Ore

- Laterite Nickel Ore: Pyrometallurgical Treatment

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Effective Gravity Beneficiation for Chromium Ore

- chrome ore processing:Advanced Magnetic Separation Processing Technology

Leave a message with your needs or comments

Add comment: