Description

In the ‘standard operation’ of mine development, the following processes are essential

1.Processability test’: To evaluate the industrial utilization value of ore veins, a small amount of materials will be used for exploratory beneficiation test.

2.Mineral processing test’: To collect ore samples within 100Kg, conduct mineral processing test in the laboratory, and estimate economic indicators.

3.Semiindustrial test’: dozens of tons of minerals are collected in the mining area, and data are obtained through test according to the ‘production operation status’as the preliminary preparation for the construction of the beneficiation plant.

4.Industrial test’: For largescale mines, industrial test is a fullprocess test in the “production” state, which serves as the basis for mine design, plant construction and production operations.

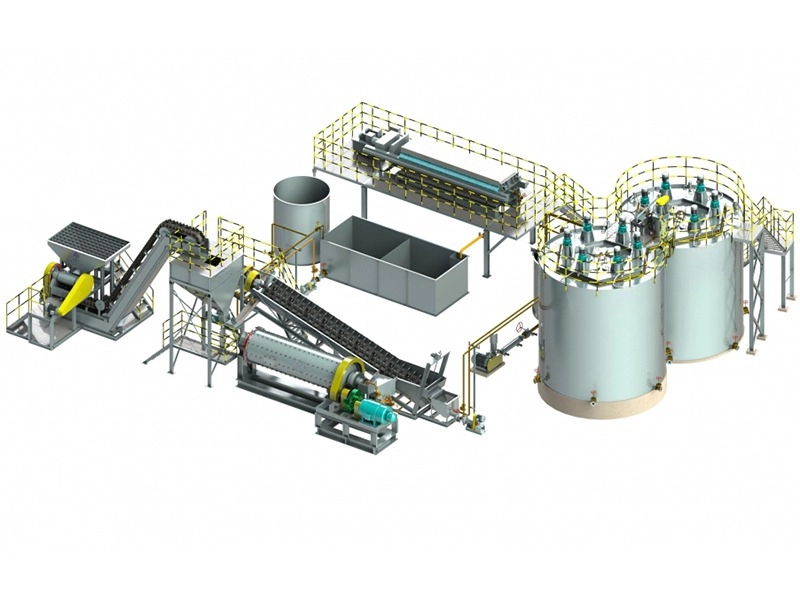

The cost of standardizing the beneficiation process is enormous and the time cycle is long. However, 10TPD Mobile Gold Leaching Plant can effectively save costs and shorten the beneficiation cycle.

Following are pictures of a group of containers exported by TUXINGSUN MININGto Nigeria for 10TPD Small Scale Gold Leaching Plant.↓↓↓

The “10TPD Small Scale Mobil Gold Leaching Plant” is a kind of mobility, which can complete all professional & non-professional tests in the mining area, and is also a beneficiation plant in production status. The Portable Gold CIL/CIP beneficiation plant perfectly avoids all test risks in the early stage of development at the lowest cost. It is the best choice to understand the ore at the lowest cost, clarify the economic benefit, and reduce the risk of mine development.

The main advantages of the gold 10TPD CIL/CIP processing plant are as follows

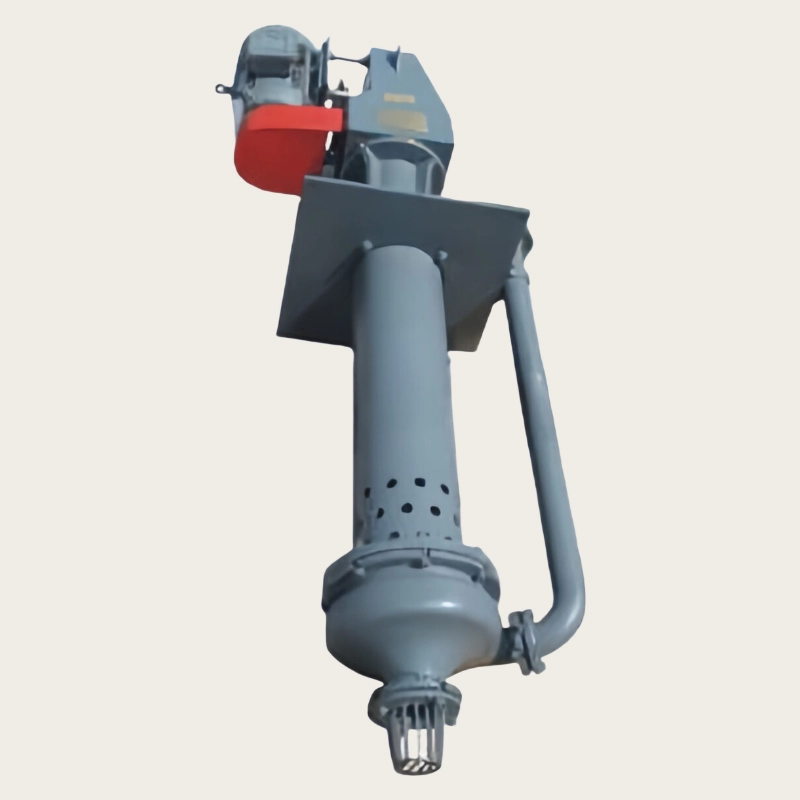

1.The 10TPD CIL/CIP processing plant is mainly applicable to oxidized quartz vein gold ore type, the mineral composition is relatively simple; the gold that exists in the ore as granular gold is grabbed by gravity separation and mixed with mercury, and other low-grade gold enters the cyanidation process for recovery.

2.The complete set of Mobile Gold Leaching Plant has been installed and debugged in the factory before leaving the factory and can be moved around according to needs without infrastructure, minimizing installation costs.

3.In most cases, the Small Portable Gold Process Plant can be put into production within three days of its arrival at the mining site.

4.Each process of the largescale CIP/CIL plant has a flow chart that including two stages of crushing, one stage of grinding, one stage of granular gold gravity separation and recovery, one stage of the leaching process, barren liquid and cyanide-containing sewage discharged from the tailing pond can all be returned to the process, no environmental pollution;

5.Gold metallurgy in site by coke or diesel oil alchemy, the gold grade of the final product exceeds 97%, and the recovery rate of cyanide reaches 90%.

6.To avoid the problem of uneven sampling in the beneficiation experiment, repeated sampling can be repeated several times and studied separately.

7.Complete a full set of beneficiation tests independently in the mining area. The 10TPD CIL/CIP processing plant integrates the whole process from the processability process of exploration to the final industrial test. It enables mine owners to perfectly understand their ore properties, and ore dressing recovery rate, and then pre-calculate investment income statements to reduce mine investment risks.

8.Small industrial production, profit every day. Reduce the pressure on funds in the early stage of mine investment.

9.It can be moved between different mining areas according to needs. Do beneficiation tests and production nearby the ore site.

10.The recovery of equipment investment can be completed within one month of normal production (there will be adjustments according to the ore grade).

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold selection process using resin slurry method

- Scheelite Flotation Method

- Nickel Ore Mixing and Separation Flotation Process

- Combined Process for Manganese Ore Magnetic Separation and Flotation

- Molybdenite Grinding and Separation Process

- Effective Flotation Processes for Copper-Molybdenum Ores

- Tantalum-Niobium Ore Combined Beneficiation Guide

Leave a message with your needs or comments

Add comment: