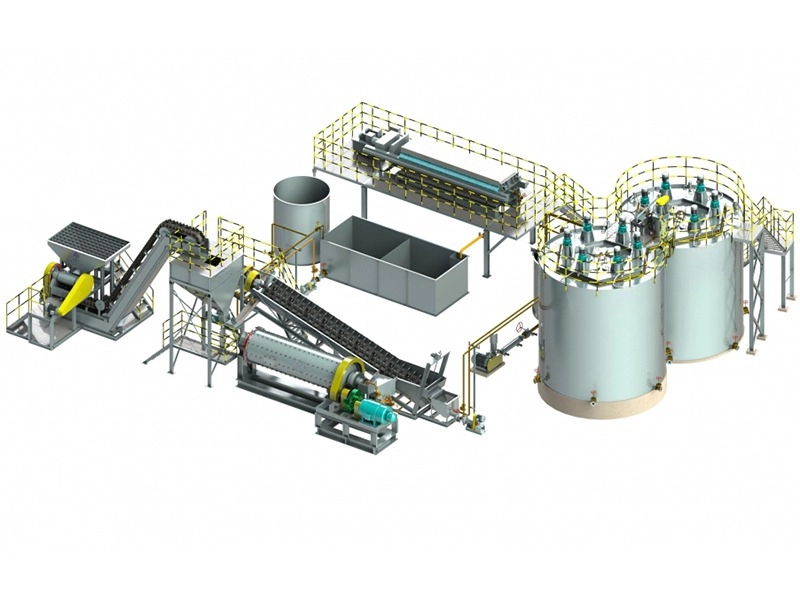

Gold mercury amalgam separator is used to treat gold-bearing heavy sand of placer gold mine and gravity concentrate of vein gold mine.

The recovery rate of gold extraction by mercury mixing cylinder can reach more than 98%. It is one of gold ore dressing equipment and gold ore purification equipment.

Description

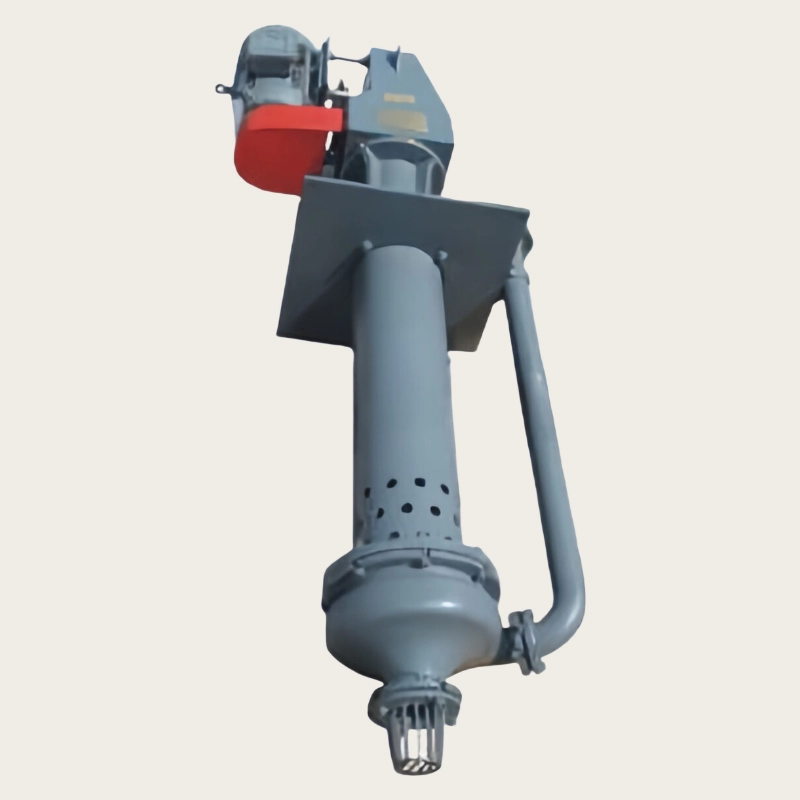

Name: amalgamation cylinder, amalgamation machine, gold amalgam, mercury mixing cylinder

Cylinder size: 420*600mm

Feeding particle size: ≤5mm

Feeding amount per time: 30-50kg

Application field: Widely used internal amalgamation equipment, used to process gold-bearing heavy sand in placer mines and selected gold concentrates in vein gold mines. It is high-efficiency internal gold amalgam equipment.

Uses: A kind of equipment used for gold or silver extraction by amalgamation in gold and silver mines.

As a kind of internal mercury mixing cylinder used in gold concentrators, the amalgamation cylinder (amalgamation machine) can reach about 90% recovery rates.

In gravity separation gold concentrates, most of the gold exists in a free state, but the surface of the gold particles is often polluted, and some gold is present in combination with other minerals or gangue. Gravity separation gold concentrate is treated with an amalgamation cylinder. The steel balls are often added to the cylinder, and the surface film of the gold particles is removed by grinding, the gold particles are dissociated from the conjoined body, and the heavy sand containing free gold particles with clean surfaces is treated.

When concentrate is used, a light amalgamation cylinder is generally used, and the amount of balls is small. Heavy-duty amalgamation cylinders are often used when dealing with heavy sand concentrates with high content of conjoined bodies and serious contamination on the surface of gold particles.

Themercury mixing cylinder is part of the internal amalgamation equipment based on the type of amalgamation. It is lined with rubber. As a result of the grinding action of the sphere, the surface of the gold particles are polluted and part of the dense film is broken, leading to forced amalgamation. Equipment amalgamation gold recovery rates are high.

Advantages

Beautiful appearance and reliable performance.

Convenient and energy-efficient operation.

Reduces mercury consumption during gold extraction and amalgamation.

Product use

Unlike manual operation, an amalgamation cylinder is a placer gold amalgamation equipment. Currently, gold is still purified by manual amalgamation in many remote and backward gold mining areas. Amalgamation is harmful to workers and the environment. Mercury is highly toxic and evaporates into the air, causing great harm. When mercury is evaporated into the air, it will be inhaled unconsciously. Further, the skin is directly in contact with mercury during the operation, and the potential harm is obvious! By the appearance of amalgamation cylinders, this problem is solved, labor is replaced, mechanical operation is realized, and the harm is greatly reduced.

| Item | Technical parameter | unit |

| Cylinder(dia*length) | 420*600 | mm |

| Volume | 75 | L |

| Rotary speed | 48 | R/min |

| Feeding size | <5 | mm |

| Feeding capacity | 30-50 | kg |

| Motor power | 3 | kw |

| Dimensions | 1600*850*1000 | mm |

| Weight | 350 | kg |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Scheelite Flotation Method

- Lead-zinc Ore Asynchronous Flotation Process

- Floatability flotation process for lead-zinc ore

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Nickel Ore Mixing and Separation Flotation Process

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

Leave a message with your needs or comments

Add comment: