Description

Name: Deoxygenation tower

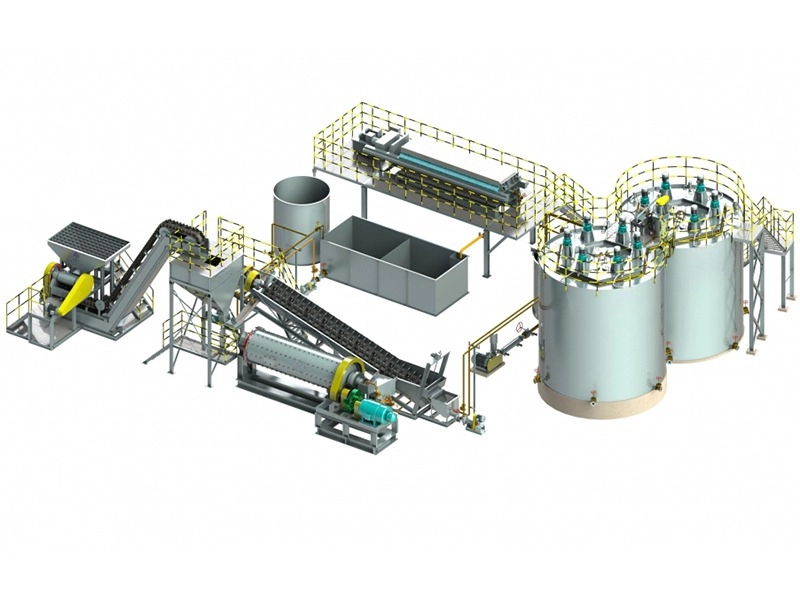

Composition: The deoxygenation tower is mainly composed of tower body, tower cover, liquid ejector, filler, liquid level regulating device and tubular liquid level gauge.

Application:During cyanidation beneficiation, vacuum deoxidation towers are used to purify precious liquids. The oxygen dissolved in your solution is detrimental to the replacement of zinc powder in the cyanide gold separation process, and it must be separated as much as possible. Vacuum deoxidation is an ideal process of deoxidation, which is carried out in the deoxidation tower.

Deoxygenation towers are the most common deoxygenation equipment currently in use. With a cylindrical cone-bottom tower body and bolted upper tower cover, it is a cylindrical tower. In the upper part of the tower body is a solution sprayer, and in the middle is a polypropylene tape braided mesh packing, which is fixed by steel welded supports and supported by sieve plates in the lower part. Provide more opportunities for the noble liquid to deoxidize since they make up the entire packing layer in the tower. A liquid level control device is provided in the lower part of the tower body for controlling the level of the deoxidizing liquid. It controls the liquid level by adjusting the opening degree of the liquid inlet valve according to the level of the liquid.

Working Principle

Deoxygenation tower solutions are sucked into the top of the tower by vacuum, diffused by the sprayer, and sprayed evenly onto the packing surface. To achieve deoxygenation, the dissolved gas in the liquid is removed by downward flow under vacuum. Through the liquid discharge port at the bottom of the cone, the deoxidized liquid is sucked out by the pump and pressed into the replacement operation. When the gauge pressure of the deoxygenation tower is 0.005~0.011Mpa, the deoxygenation rate can reach more than 95%, and the oxygen content of the deoxygenation liquid is below 0.5g/m3. Each specification specifies a minimum height of 3m for the deoxygenation tower.

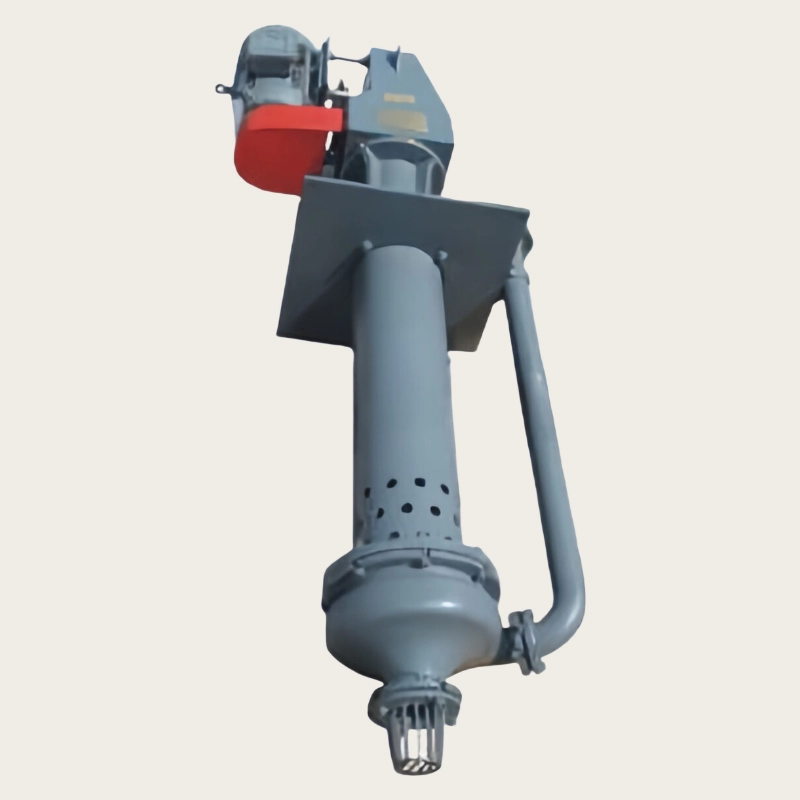

Water jet pumps are generally used for deoxygenation tower vacuum equipment.

Product Advantages

In cyanide beneficiation, the deoxygenation tower is the main deoxygenation equipment for purifying precious liquids. Oxygen dissolved in the noble liquid is harmful to zinc replacement during gold cyanidation. It should be isolated as much as possible.

Deoxygenation is an ideal process for deoxygenation, which is carried out in a deoxygenation tower. Our company developed a new plastic mesh filler to overcome the drawbacks of point wave fillers that affect the deoxidation effect of alkaline cyanide liquid by forming calcium.

| Specification | Handing medium | Working temperature | Capacity of spraying(m3/h) | Weight(kg) |

| φ7000*3000 | Cyanide liquor | Normal temperature | 16-37.5 | 550 |

| φ1000*3000(3500) | Cyanide liquor | Normal temperature | 16-37.5 | 700(774) |

| φ1400*1400 | Cyanide liquor | Normal temperature | 16-37.5 | 2304 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Copper ore mixed flotation process

- Branch serial flow flotation process for lead-zinc ore

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Lithium ore combined beneficiation process

- Effective Gravity Beneficiation for Chromium Ore

- Effective antimony ore gravity separation method

- Manganese Ore Separation: Gravity and Magnetic Methods

Leave a message with your needs or comments

Add comment: