West Africa 100tph Alluvial Gold Ore Washing Project with trommel screen,

vibrating sluice, fixed gold sluice box, shaking table etc

100t/h Alluvial Gold Mine Washing Project in West Africa

In the heart of West Africa, a ground-breaking 100 tons/hour alluvial gold ore washing project is underway, using state-of-the-art equipment such as rotating screens, vibrating washers, fixed wash boxes, vibrating tables, etc. . This ambitious effort aims to extract gold from alluvial deposits, showcasing the region's rich natural resources and the innovative technologies used to exploit them.

The alluvial gold mining process involves extracting gold from sedimentary deposits in river beds and floodplains. Unlike traditional hard rock mining, alluvial mining relies on natural erosion and deposition processes to concentrate gold particles, making it a cost-effective and environmentally friendly method of gold extraction.

The core of the 100t/h alluvial gold mine washing project in West Africa is the use of cutting-edge equipment to efficiently separate gold from surrounding sediments. Rotating screens are a key component of the cleaning process, sifting through alluvial material to separate larger rocks and debris from finer sediments containing gold particles. This initial screening process is critical in preparing the material for further processing.

After the initial screening, the vibration cleaning machine comes into play to effectively clean and separate the finer sediments to extract the gold particles. This high-frequency vibration equipment ensures thorough cleaning and separation, maximizing gold recovery from alluvial materials.

In addition to the vibrating cleaning machine, the project also uses stationary cleaning tanks to provide a stationary cleaning solution for alluvial materials. These stationary wash boxes are designed to efficiently capture and concentrate gold particles, further enhancing the overall recovery process.

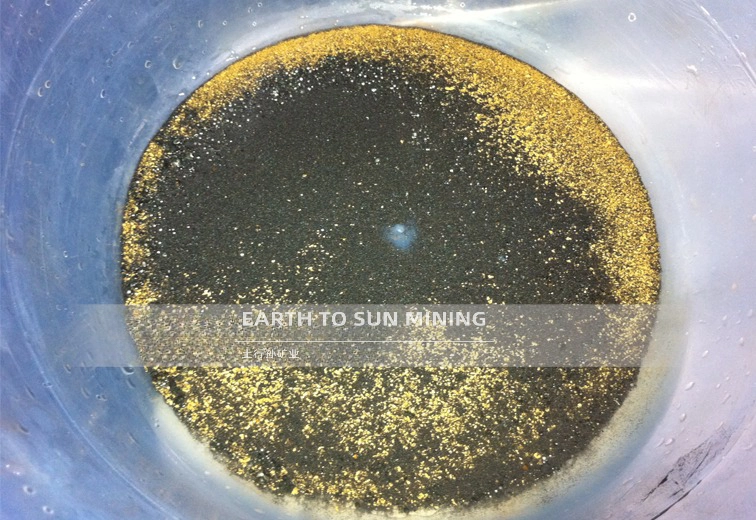

Once the gold-bearing sediments have been washed and concentrated, shakers are used to further refine the gold and separate it from remaining impurities. This specialized equipment uses vibrations to separate heavier gold particles from lighter materials, producing a high-grade concentrate that can be further processed.

The 100 t/h alluvial gold wash project in West Africa represents a significant investment in advanced mining technology and infrastructure, underscoring the region’s commitment to sustainable and responsible resource extraction. By using modern equipment and technology, the project aims to maximize gold recovery while minimizing environmental impact, setting a new standard for alluvial mining operations in the region.

In addition, the project is expected to create jobs, contribute to the local economy and promote economic growth and development in the surrounding communities. As the project progresses, it will become a model for responsible mining practices and demonstrate the potential for sustainable resource extraction in West Africa.

summary

the 100 t/h alluvial gold washing project in West Africa is a testament to the region’s natural wealth and the innovative technologies being used to unlock its potential. This project uses advanced equipment such as rotating screens, vibrating washers, fixed wash boxes, and shaking tables, taking an important step in the sustainable mining of placer gold. As the project continues to unfold, it will have a lasting impact on the mining industry in West Africa and beyond.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Lithium ore magnetic separation process

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

- Chromite Gravity and Magnetic Separation Process

- Effective Flotation Processes for Copper-Molybdenum Ores

- Polymetallic Molybdenum Ore Processing: Magnetic Separation and Flotation

- Tantalum-Niobium Ore Processing: Gravity, Magnetic, and Electric Separation

- Barite Fluorite Ore Flotation Process for Efficient Separation

Leave a message with your needs or comments

Add comment: