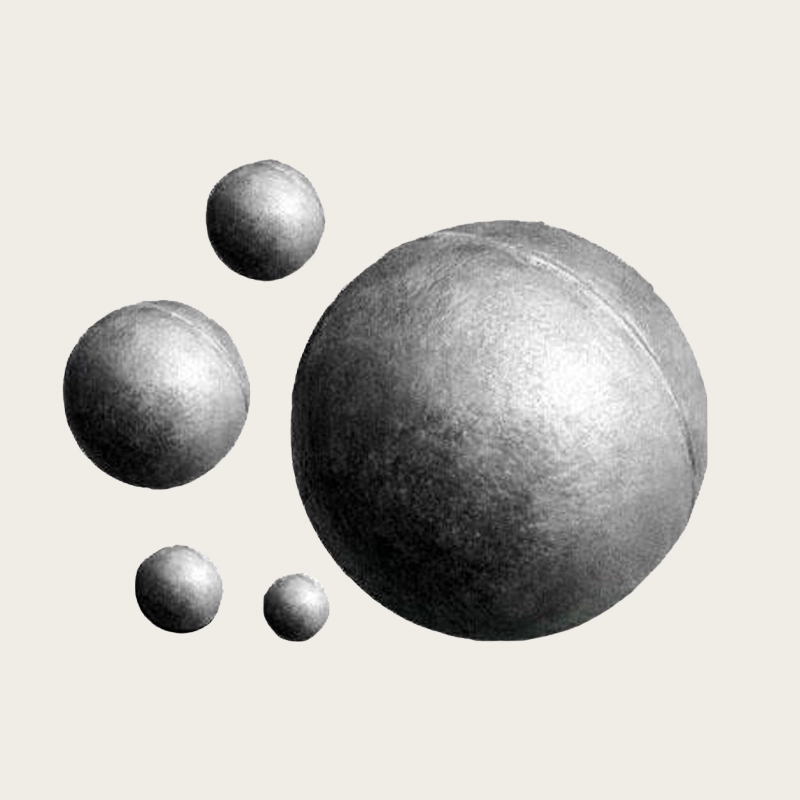

Model:Low chromium alloy grinding ball

Weight:0.11~8.74kg

Surface hardness:≥45 HRC

Application range:It is widely used in powder preparation and superfine deep processing of industries, such as building materials, mine, chemical engineering, ceramic material, papermaking, magnetic materials.

Low Chromium Alloy Grinding Ball

Introduction

Low chromium alloy grinding ball is widely used in powder preparation and superfine deep processing of industries, such as building materials, mine, chemical engineering, ceramic material, paper-making, magnetic materials. Its surface hardness can up to more than 45HRC, hardness gradient is evenly distributed. It has good toughness and breaking resistance is 5 times than ordinary grinding ball. There is no deformation. It increases recovery rate of concentrate and production capacity of mill, prolongs the service life of liner plate of the mill, and reduces the cost of production.

Production Technology

Medium frequency furnace smelts high quality steel scrap, chromium alloy and other alloy materials first, after micro alloying processing is castmolding with steel model.

Constant temperature pouring ensures there is no sand inclusion, stoma, collapse and other quality defects.

Heat treatment oil quenching process, quenching and tempering will change internal structure of the ball, reduce the internal stress of sphere, ensure breaking

rate to further improve the performance after quenching.

Semi-finished product and finished product adopt advanced spectrum detection to ensure the stability of chemical composition and performance.

Specification

| specification(mm) | unit weight(kg) | quantity(pc/t) |

| Φ30 | 0.11 | 9090 |

| Φ40 | 0.25 | 3891 |

| Φ50 | 0.50 | 2000 |

| Φ60 | 0.86 | 1153 |

| Φ70 | 1.37 | 729 |

| Φ80 | 2.05 | 487 |

| Φ90 | 2.90 | 345 |

| Φ100 | 4.00 | 250 |

| Φ110 | 5.30 | 188 |

| Φ120 | 6.80 | 147 |

| Φ130 | 7.70 | 129 |

| Φ140 | 8.74 | 113 |

We can provide customized design according to our clients’ demands and also refine our products by our clients’ feedback.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Selective grinding and agglomeration flotation process for bauxite

- Tin ore gravity+flotation process

- Intense Magnetic Separation Process for Iron Ore

- Iron ore positive flotation process

- Iron Ore Combined Beneficiation Process

- Gold Mine Heap Leaching: Optimal Process

- Gold Ore Carbon Slurry Beneficiation Process

Leave a message with your needs or comments

Add comment: