Zircon sand, a valuable mineral resource, is widely used in various industries due to its unique properties and applications. The symbiotic ores found in zircon sand, such as magnetite, ilmenite, rutile, and monazite, make it a versatile raw material for the production of zirconate refractory bricks and ceramic casting. The main producing areas of zircon sand are located in Australia, the United States, Brazil, and coastal regions of China, including Hainan, Guangdong, Fujian, and the Shandong Peninsula. These areas are rich in zirconium mines, with large-scale deposits in Haifeng, Guangdong, and Wanning, Hainan, making them ideal for mechanized mining and comprehensive development.

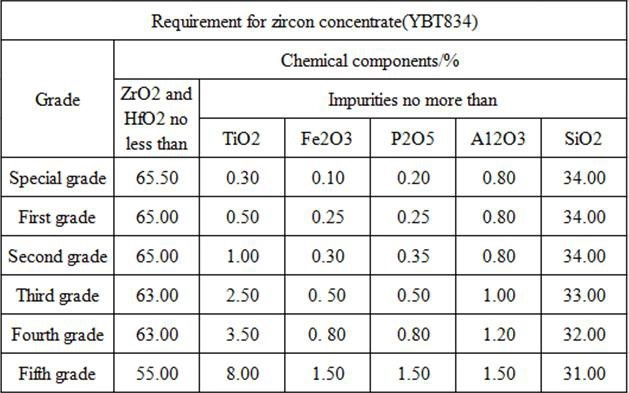

this is the zircon sand content grade chart: 65.5% is the best content (Extreme level), the 55% is the fifth content, generally, we can make your zircon sand to 65%, if you want higher, we can equip one more electrostatic separator for higher content.

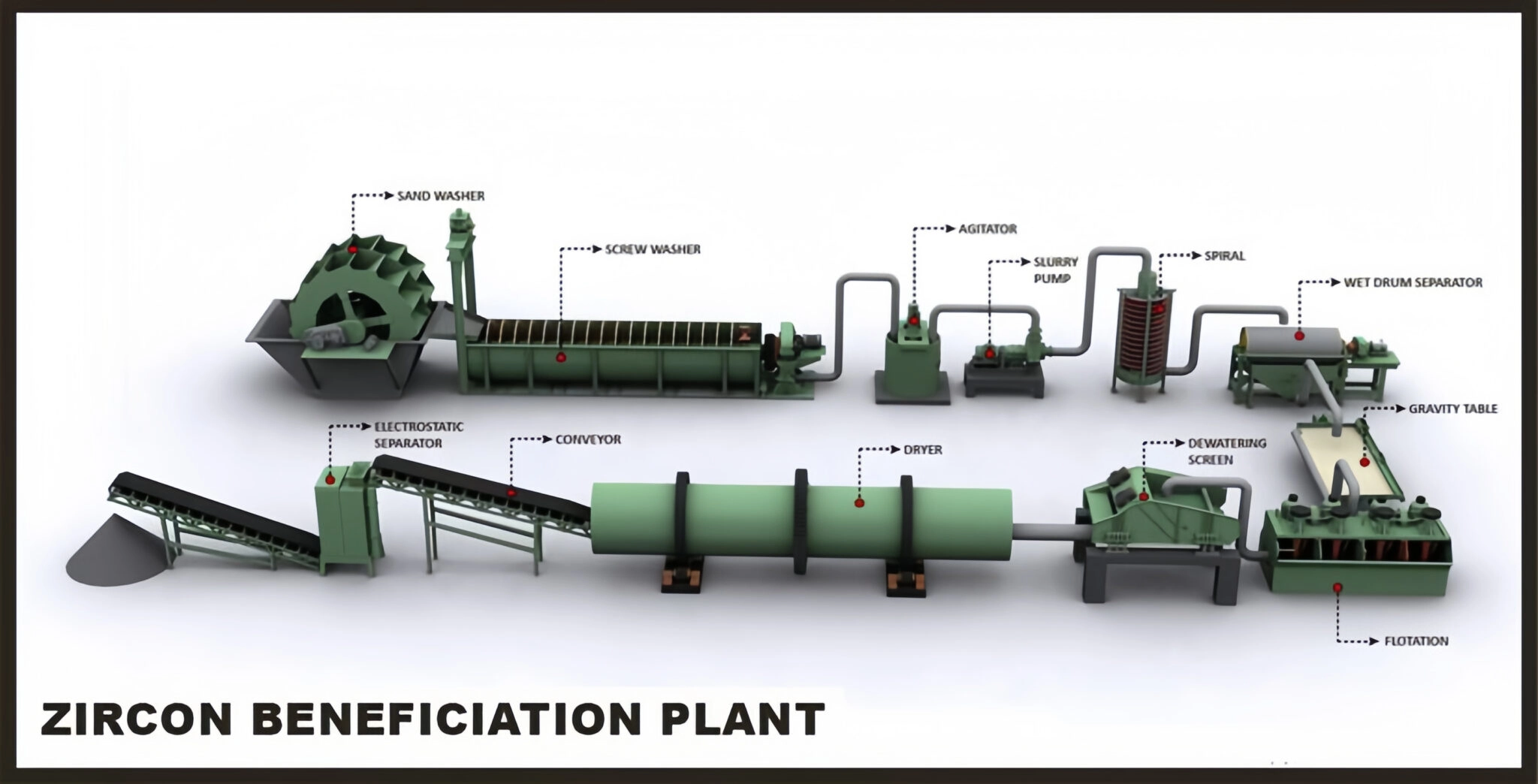

The beneficiation processes for zircon sand involve various techniques such as gravity separation, magnetic separation, and electric separation. Re-selection methods, including the use of spiral chutes or shakers, are employed to remove silica from zircon sand. Magnetic separation techniques, utilizing wet or dry magnetic separators, are utilized to separate zircon sand from ilmenite, with the wet magnetic separator being particularly effective for zircon sand particles of 20um size. Electric separation methods, employing double-roller and arc plate electric separators, are used to separate rutile and zircon sand. Comparing the zircon sand treatment process to other mineral beneficiation processes, such as copper flotation, chromium ore treatment, and gold beneficiation, reveals its simplicity and ease of operation, with the only requirement being power for the use of electrostatic separators in high-grade zircon sand recovery.

summary

zircon sand plays a crucial role in various industrial applications, and its widespread availability in key producing regions such as Australia, the United States, Brazil, and China ensures a steady supply for global markets. The comprehensive development and utilization of zirconium mines in coastal areas of China, particularly in Hainan, Guangdong, Fujian, and the Shandong Peninsula, highlight the potential for large-scale mechanized mining and efficient extraction of zircon sand. The beneficiation processes for zircon sand, including re-selection, magnetic separation, and electric separation, underscore the simplicity and effectiveness of these techniques, making zircon sand treatment accessible and practical in comparison to other mineral processing methods. With its valuable properties and versatile applications, zircon sand continues to be a valuable resource in the global market, driving innovation and development in various industries.

- Random article

- Popular articles

- Popular comments

- Understanding the Gold Mine Flotation Process

- Carbon leaching beneficiation process for gold mines

- Nickel Ore Mixing and Separation Flotation Process

- Lithium ore reverse flotation process

- Lithium ore combined beneficiation process

- Combined Process for Manganese Ore Magnetic Separation and Flotation

- Tantalum-Niobium Ore Processing: Gravity, Magnetic, and Electric Separation

Leave a message with your needs or comments

Add comment: